Mugs with prints on them are great keepsakes and presents. DIY mug printing is possible with the use of a cup printing machine, an image or text, and an iron. The image or text is transferred to the mug by the heat of the iron. If you don't have access to a sublimation printer, or you can send your text or image to a printing company to have it transferred onto a mug.

Glued Cups

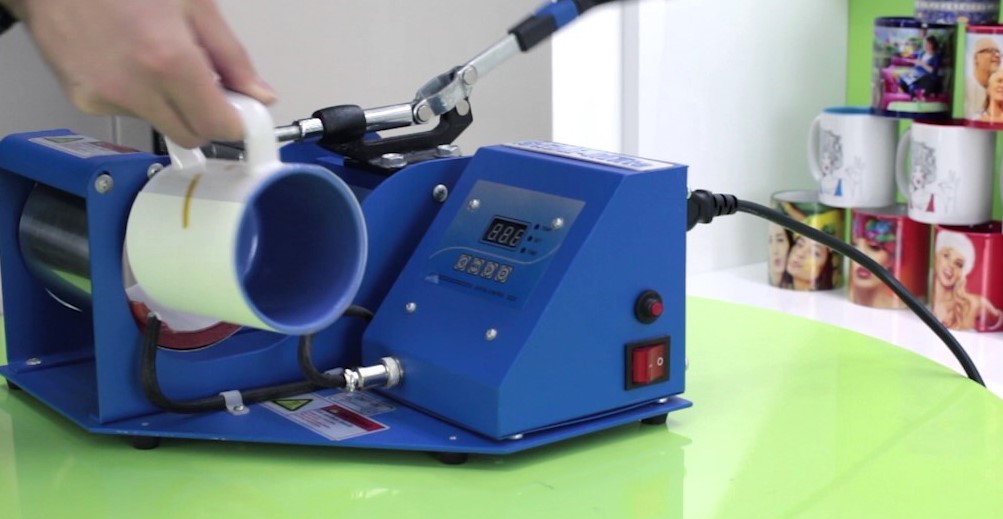

Coated Mugs have a plastic coating specifically made to "accept" an imprint. It's imperative that this surface be white, as any other hue will distort the printed ink. Consider how blue and yellow combine to form green. This is one of the best types of cup printing machine.

Glassware Without Coating

When you see colored mugs, chances are they are uncoated. Typically, these are bare ceramic, meaning they have no protective layers. The different hues could be the result of painting, dying, or some other process. There is no such plastic-like layer on them, though.

Conical and Cylindrical Cups

You will mostly be printing on either cylindrical or conical mugs. These can be cylindrical (with the same diameter at the top and bottom) or conical (with the top and bottom being different sizes), with the former being preferable for printing on a mug.

Printer With White Toner

The newest method for printing on mugs is called white toner printing, and it uses L.E.D. printers like the OKI8432wt to print full-color transfers on specially coated transfer paper. This method is simply a modern adaption of an older technology.

Earning By Mugs Printing

There's a wealth of material to disseminate about marketing and promoting custom printed mugs, but before diving in, let's take a look at some numbers. The average price of a blank ceramic mug is between $2 and $4. Estimated price range for printing on a mug: $0.05 - $1

Art Making.

CorelDraw, Photoshop, or another graphics editing programme is recommended for the design phase. An online business such as coldesi-graphics.com can help you out if you don't have any artistic ability.

Making Plastic Pad Prints

For those who have never heard of it before, pad printing involves combining a solvent-based pad printing ink with a hardener and other ingredients. The pad printing ink was picked out especially for the substrate. A total of seven plastic-printing pad inks are available from Inkcaps.

Pre-Treatment

Pretreatment is not required for most solvent-sensitive goods. For this reason, pad printing ink might stick to the object since the ink's solvent will reduce the product's natural resistance to ink. Pretreatment is necessary for products made of solvent-resistant materials such as polypropylene, nylon, high-density polyethylene, and similar materials.

Use of Ultraviolet Rays for Plastic Printing

Even when using UV ink on plastic, there are similar factors to take into account. UV printing, often known as UV inkjet printing, is a direct-to-substrate printing method. Design software (Photoshop or Illustrator) is used to develop and modify the artwork, which is then transmitted to a printer for printing.